Hinge Installation Guide

Cabinet Hinge Installation Guide | From Selection to Fine Adjustment

International Terms (Full Overlay / Half Overlay / Inset) × Taiwan Field Terms (Straight Arm / Half-Crank / Inset Arm) × Shop-Floor Workflow

1) Key Terms & Mapping

| International Category | English Term | Taiwan Field Term | Key Notes |

|---|---|---|---|

| Full Overlay | Full Overlay | 6 fen (Straight Arm) | Door fully covers the cabinet side panel edge; most common for single doors and system cabinetry. |

| Half Overlay | Half Overlay | 3 fen (Half-Crank) | Two doors share one center partition; each door takes half of the overlay on the shared panel. |

| Inset | Inset | Inset (Large Bend) | Door sits inside the cabinet opening; flush and clean look, higher sensitivity to tolerances and gap planning. |

Tip: On-site communication often uses “straight arm / half-crank / inset arm.” For international sourcing and RFQs, use “Full Overlay / Half Overlay / Inset.”

2) How to Choose | One-Pass Decision

- Door-to-Cabinet Relationship: Full coverage = Full Overlay; shared partition = Half Overlay; flush inside = Inset.

- Environment: General indoor use = cold-rolled steel; kitchen/bath/coastal/high humidity = SUS304 stainless steel.

- Feature Priority: Quiet closing = Soft-Close; frequent removal/service = Clip-on / Detachable (Quick Release).

- Structural Stability: For heavier doors or high-cycle usage, prefer 4-hole base or airplane plate base for better fastening stability.

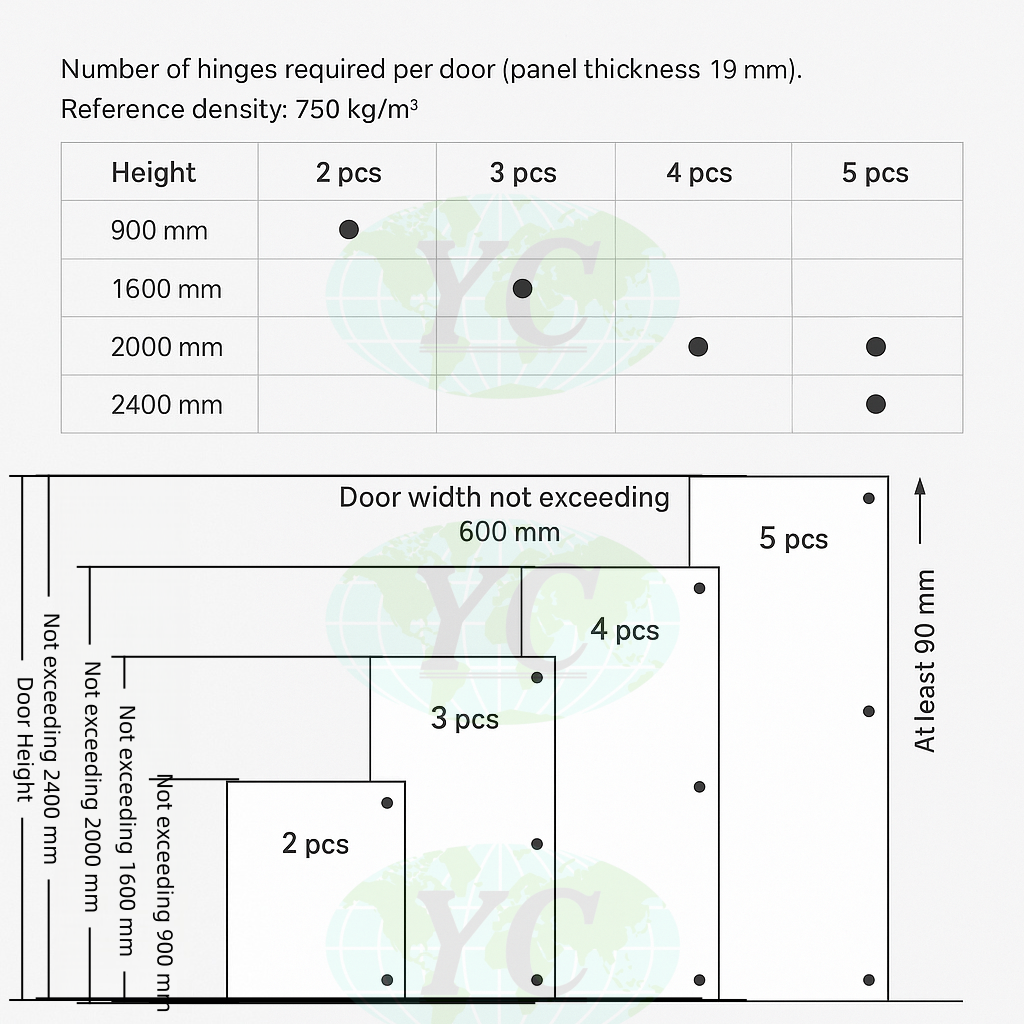

3) Opening Angle & Tolerance

- Standard concealed hinges are typically nominal 90°. Due to hinge geometry, part tolerances, and installation variables, real-world results commonly land around 90–100°.

- If the door hits a wall or handle interferes: adjust cup setback (C dimension) and base position first; if needed, reposition the handle or add a door stop.

- Special angles: 105° (often preferred in US-style applications) or 155°/165° (wide access, corner cabinets, pull-out clearance) should be addressed by selecting a dedicated hinge geometry rather than forcing a standard hinge to “behave like” a wide-angle hinge.

- Important clarification: “Clip-on / Detachable” (quick release) improves installation and maintenance efficiency. It does not change the opening angle. Opening angle is determined by the hinge design (e.g., 165° geometry).

4) Door Boring & Design Dimensions

| Item | Typical Recommendation | Notes |

|---|---|---|

| Cup Diameter | φ35 (mainstream), φ40 (optional) | φ35 is the industry mainstream; φ40 is used for special requirements (depends on hinge and door design). |

| Cup Depth | Standard: ~11–12 mm | Shallow cup: ~9–9.5 mm | Standard concealed hinges usually use ~11–12 mm. Shallow-cup hinges (e.g., φ35 with ~9.5 mm cup depth) are intended for thin doors or when boring depth is limited. Always validate with samples and the chosen hinge spec. |

| Cup Setback (C Dimension) | 3–6 mm | Controls overlay and gaps; too large/small may cause poor closing, interference, or visible gap issues. |

| Door Thickness Range | 15–22 mm (common) | For thicker/heavier doors, verify hinge quantity, base type, and screw holding strength. |

| Door-to-Cabinet Gap | 1.5–2.0 mm | Allows for laminate/paint thickness and assembly tolerances; prevents rubbing and rebound interference. |

Reminder: The above are common engineering references. Final settings must be validated with real samples, jigs, and door materials (plywood, solid wood, aluminum frame glass, etc.).

5) Standard Installation Checklist

- Mark & Position: Confirm C dimension, base height, and target reveal/gap.

- Bore the Cup: Use a Forstner bit for φ35 (or φ40 when specified). Set depth per hinge spec (standard ~11–12 mm; shallow cup ~9–9.5 mm).

- Mount the Cup: Place the cup into the hole and fasten with screws.

- Fix the Base: Install the base on the cabinet side panel (2-hole / 4-hole / airplane plate).

- Hang & Adjust: Use 3-way adjustment (in-out / up-down / left-right) to align gaps and flushness.

- Functional Test: Open/close multiple cycles. If interference occurs, revisit cup setback and base position first; then handle position/door stop as needed.

6) Material & Surface Finish

| Item | Options / External Spec Language | Recommended Use |

|---|---|---|

| Material | Cold-rolled steel (general) / SUS304 stainless steel (corrosion resistance) | General furniture: cold-rolled steel. High humidity/coastal/kitchen & bath: SUS304. |

| Finish | Nickel finish (typical) / Stainless natural finish (for SUS304 series) | For consistent appearance and stable supply. If salt spray or special coating is required, define testing/grade in RFQ before ordering. |

7) FAQ

Should I install the door side first or cabinet side first?

My door hits a wall or handle—what should I do?

How do I quickly identify Full Overlay / Half Overlay / Inset?

Can I mix parts across different hinge series?

8) Example Model Quick Reference (Links)

| Category | Model | Positioning | Notes (Selection Logic) | Links |

|---|---|---|---|---|

| Standard concealed (90–100°) | H1066 | General concealed hinge platform | Common selection for projects; supports Full Overlay / Half Overlay / Inset via arm/base combinations. Ideal for stable sourcing and scaling. | CN / EN |

| Standard concealed (90–100°) | H1066SC | Soft-close version (same platform) | Soft-close for quiet closing. Note: some pages present H1066 & H1066SC as the same platform page; validate model options on the page. | CN / EN |

| Standard concealed (90°) | H1221 | Independent hinge system | Different aesthetics/arm/base planning vs H1066 series; sample-fit is recommended before replacement. | CN / EN |

| Shallow cup (φ35 / ~9.5 mm cup depth) | H1235 / H1235SC | When boring depth is limited | Still φ35 cup diameter, but shallow cup depth. Use for thin doors or drilling depth constraints; validate with door structure and jig settings. | CN / EN |

| 105° (often US preference) | H1237SC | 105° opening requirement | Choose when 105° is specified. Re-check overlay/C and base method to prevent interference and ensure proper reveal. | CN / EN |

| 155° wide opening | H1252SC | 155° + soft-close (clip-on / airplane base) | For better access and clearance vs standard hinges. Suitable when a wider swing is required; still requires proper stop planning to avoid over-travel and collisions. | CN / EN |

| 165° wide-angle | H1241SC | 165° + soft-close + clip-on / detachable | For corner cabinets, pull-out trays, and maximizing access. Wide-angle = clearance; clip-on = easier installation/removal (two different benefits). | CN / EN |

| 165° wide-angle | H1230 | 165° (standard / fixed style) | Choose when 165° is required but soft-close is not needed. Good for specified cabinet designs that prefer fixed structure. | CN / EN |

| 165° wide-angle | H1228 | 165° + raised base (clearance design) | Used when cabinet structure needs base height for avoidance/clearance. Validate base height and door reveal early in design. | CN / EN |

| Glass door (clamp type) | H1226 / H1226SC | Glass door hinge (rectangular / clamp structure) | Avoid φ35 cup drilling on glass. Select by glass thickness/door weight and the specified clamp + gasket configuration. | CN / EN |

| SUS304 stainless steel | H1242SC | SUS304 + soft-close (high corrosion resistance) | Best for humid/coastal/kitchen & bath. Confirm screw material, avoid mixed-metal corrosion in harsh environments when required. | CN / EN |

| Exposed hinge (non-cup) | H1212 / H1212SC | German hinge (4" / 90° / 1.1mm) | Traditional exposed hinge series. Not a φ35 cup system; choose when an exposed hinge structure is specified by design. | CN / EN |