Ball-Bearing Drawer Slides Installation Guide|Dimensional Clearances, Tolerances, Installation Steps & Q&A

Ball-Bearing Slides — Key Installation Summary

| Topic | Value / Spec | Notes / Cautions |

|---|---|---|

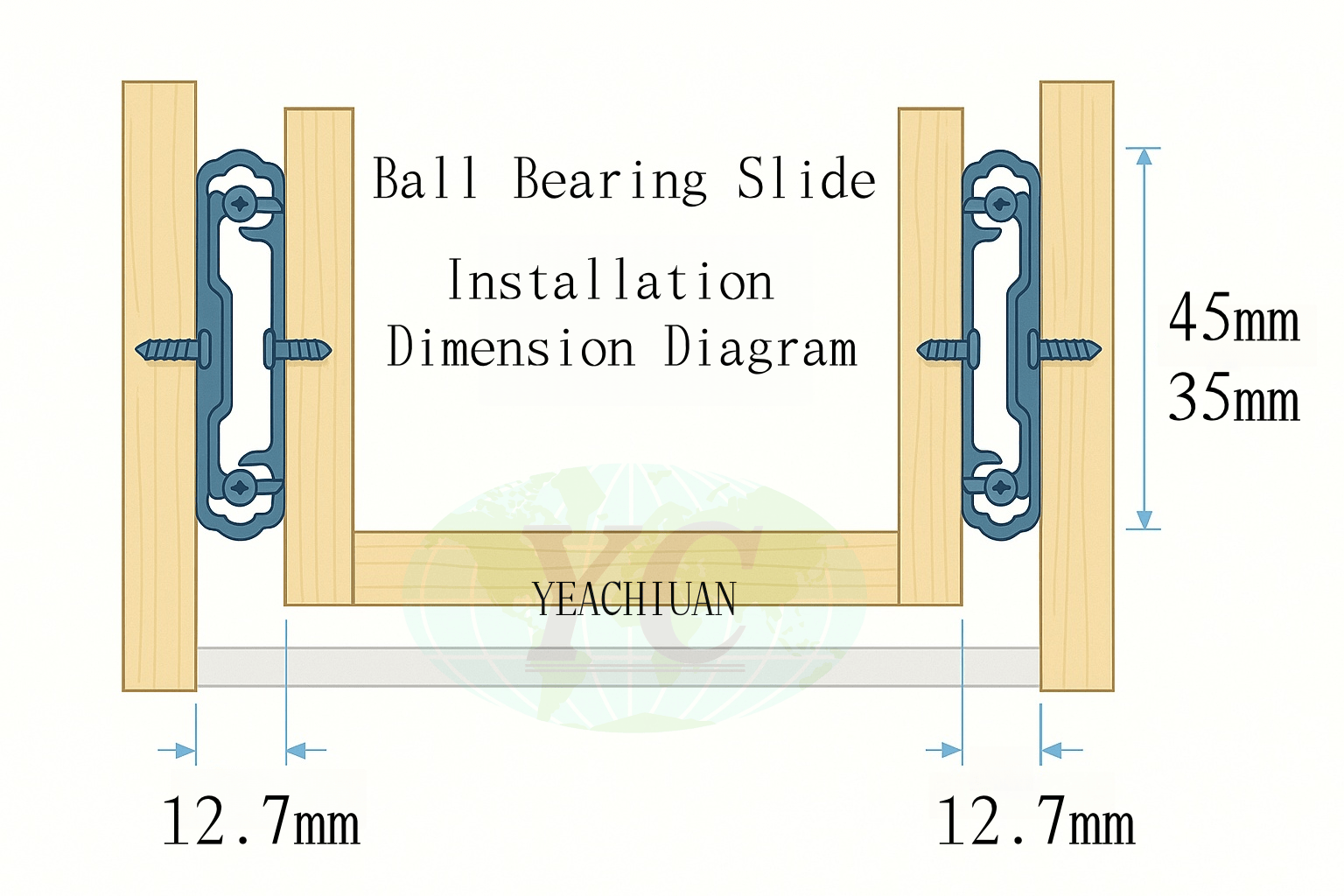

| Side Space | 12.7 mm (1/2") per side; typical tolerance +0.8 / −0 mm | Common for ~100 lb class; positive tolerance avoids compressing raceways. Soft-close variants tolerate minor fit errors better. |

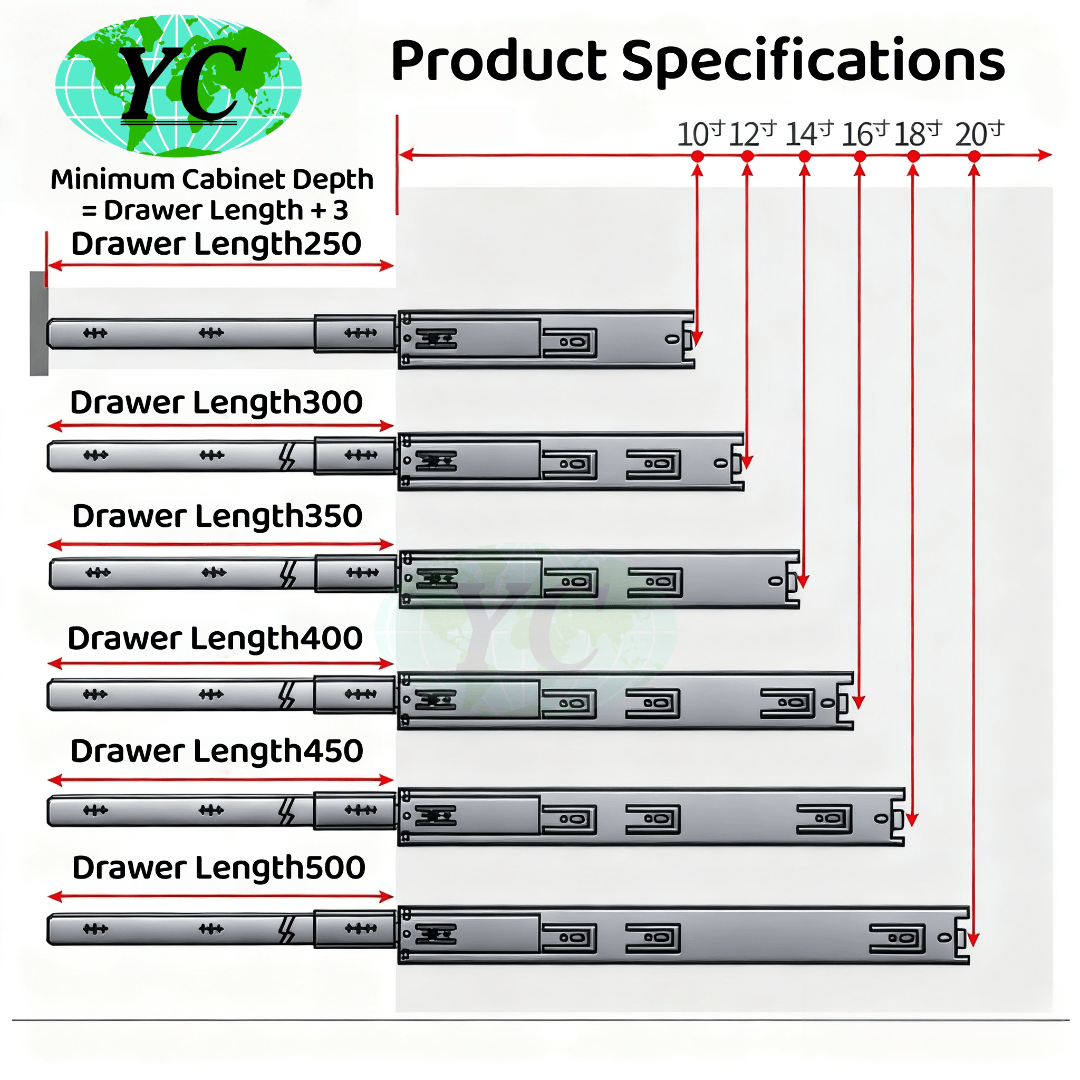

| Drawer Depth | Drawer depth = Nominal slide length | Cabinet clear depth ≥ nominal length + 3–5 mm. Reserve tail travel for the soft-close module to prevent rear interference. |

| Drawer Width | Outer width = Opening width − 25.4 mm (−1"); some models allow up to −27 mm (−1-1/16") | Matches 1/2" per side. If needed, reduce another 0.4–1.0 mm total to absorb assembly variation. |

| Minimum Drawer Height (Ref.) | Slide body height ≈ 45.5–45.7 mm (≈1.79"–1.80") | Keep clearance between drawer bottom and slide/base; varies slightly by model. |

| Max Drawer Width (Recommended) | ≤ 24" (typical for this class) | Over-wide drawers may sag or wear unevenly at full extension; always verify with the specific datasheet. |

| Recommended Screws | #6 × 5/8" (typical) or equivalent; 32 mm systems: Euro screws applicable | Use slotted holes for alignment then fix with round holes; moderate torque to avoid distortion. |

Design Formulas

| Item | Formula | Example (Opening 500 mm / 19-11/16") |

|---|---|---|

| Drawer Outer Width | Opening − (2 × 12.7 mm) = Opening − 25.4 mm (≈ Opening − 1") | 500 − 25.4 = 474.6 mm (≈ 18-11/16") |

| Drawer Depth | = Nominal slide length (e.g., 18"; common metric equivalents 450–457 mm) | 450 mm (18"); cabinet clear depth ≥ 450 + 3–5 mm |

| Side-Space Tolerance | Nominal 12.7 mm/side; consider +0.2–0.5 mm/side (reduce drawer width 0.4–1.0 mm total) | 12.9–13.2 mm/side improves mating and soft-close stability |

| Nominal Length (in) | Metric Equivalent (common supply) | Drawer Depth (= Nominal) | Required Cabinet Clear Depth |

|---|---|---|---|

| 10" | ≈ 254 mm (commonly 250/254 mm) | ~250–254 mm | ≥ Nominal + 3–5 mm |

| 12" | ≈ 305 mm (commonly 300/305 mm) | ~300–305 mm | ≥ Nominal + 3–5 mm |

| 14" | ≈ 356 mm (commonly 350/355/356 mm) | ~350–356 mm | ≥ Nominal + 3–5 mm |

| 16" | ≈ 406 mm (commonly 400/406 mm) | ~400–406 mm | ≥ Nominal + 3–5 mm |

| 18" | ≈ 457 mm (commonly 450/457 mm) | ~450–457 mm | ≥ Nominal + 3–5 mm |

| 20" | ≈ 508 mm (commonly 500/508 mm) | ~500–508 mm | ≥ Nominal + 3–5 mm |

| 22" | ≈ 559 mm (commonly 550/559 mm) | ~550–559 mm | ≥ Nominal + 3–5 mm |

| 24" | ≈ 610 mm (commonly 600/610 mm) | ~600–610 mm | ≥ Nominal + 3–5 mm |

Standard Installation (Practical SOP)

| Step | Operation Tips | Quality Check |

|---|---|---|

| 1. Separate & Inspect | Separate inner/middle/outer members; clean raceways; test free travel | No binding/noise at no-load cycling |

| 2. Cabinet (Outer Member) | Reference base line; tack with slotted holes first; keep linear & level; face-frame: use front/back brackets/spacers | Level/collinearity ≤ 1 mm; no inward/outward bulge at front |

| 3. Drawer (Inner Member) | Follow side-panel centerline; tune via slotted holes, then fix with round holes; 32 mm jig improves repeatability | L/R height difference ≤ 1 mm; side space within spec |

| 4. Engagement Test | Push in to latch; cycle 5–10×; verify soft-close completes Easy-Close travel | No rebound gap; end positions precise |

| 5. Final Tuning | Shim 0.5–1.0 mm if required; control screw torque; adjust panel reveals | Even reveals; no scraping/uneven wear |

Deep Q&A (Common Engineering Scenarios)

| Issue | Professional Answer | Prevention / Remedy |

|---|---|---|

| Drawer won’t go fully in | Insufficient cabinet clear depth (no extra 3–5 mm) or front interference; soft-close module bottoming out | Verify depth & tail travel; use brackets/spacers for face-frame |

| Rough/noisy on first install | Side space too tight or rails out of level; over-torqued screws distort members | Recheck 1/2" per side + tolerance; re-locate via slotted holes; shim if needed |

| Bounce-back / won’t stay closed | Soft-close/hold-in misalignment or fore/aft offset | Adjust via slotted holes (vertical & fore/aft); confirm anti-rebound/soft-close engagement |

| Which screws? | Commonly #6×5/8" or equivalent; Euro screws for 32 mm systems | Slot to position, round holes to fix; avoid over-length screws |

| How wide can the drawer be? | Typically ≤ 24" for this class; verify datasheet | Check “Max Drawer Width” for the exact model before shipment |

| Use WD-40 as lubricant? | Not recommended; it’s a penetrating cleaner that removes grease and may affect plastics | Use white grease or silicone oil; do not spray into damper assembly |

Maintenance

| Frequency | Task | Focus |

|---|---|---|

| Every 3–6 months | Dust removal, check fasteners, replenish white grease/silicone oil | Shorten interval in dusty sites; investigate noise/rebound immediately |

| Long-term | Operate at ≤ 70% of rated load for continuous service | Mitigates uneven wear/deflection; extends service life |

SEO Block

Disclaimer

| The dimensions, formulas, and installation/maintenance tips summarize common practices for side-mount ball-bearing slides and public technical references, for engineering reference only. Always follow the latest manuals/datasheets for the specific brand and model. |

| Variations in materials, build precision, site conditions, and usage frequency can affect results. This content provides no express or implied warranty. Installation and use should be independently assessed and trial-fitted by qualified personnel based on actual conditions. |

| We are not liable for direct, indirect, incidental, or consequential losses arising from deviations such as not following OEM instructions, lack of maintenance, operation beyond recommended loads, or use in special environments (e.g., high temperature, humidity, chemicals, heavy contamination, strong vibration). |

| For performance and cosmetic consistency, conduct pilot builds and necessary stress/durability tests prior to mass production or delivery. In case of discrepancy or doubt versus OEM documents, the latest OEM technical documents and on-site verification prevail. |