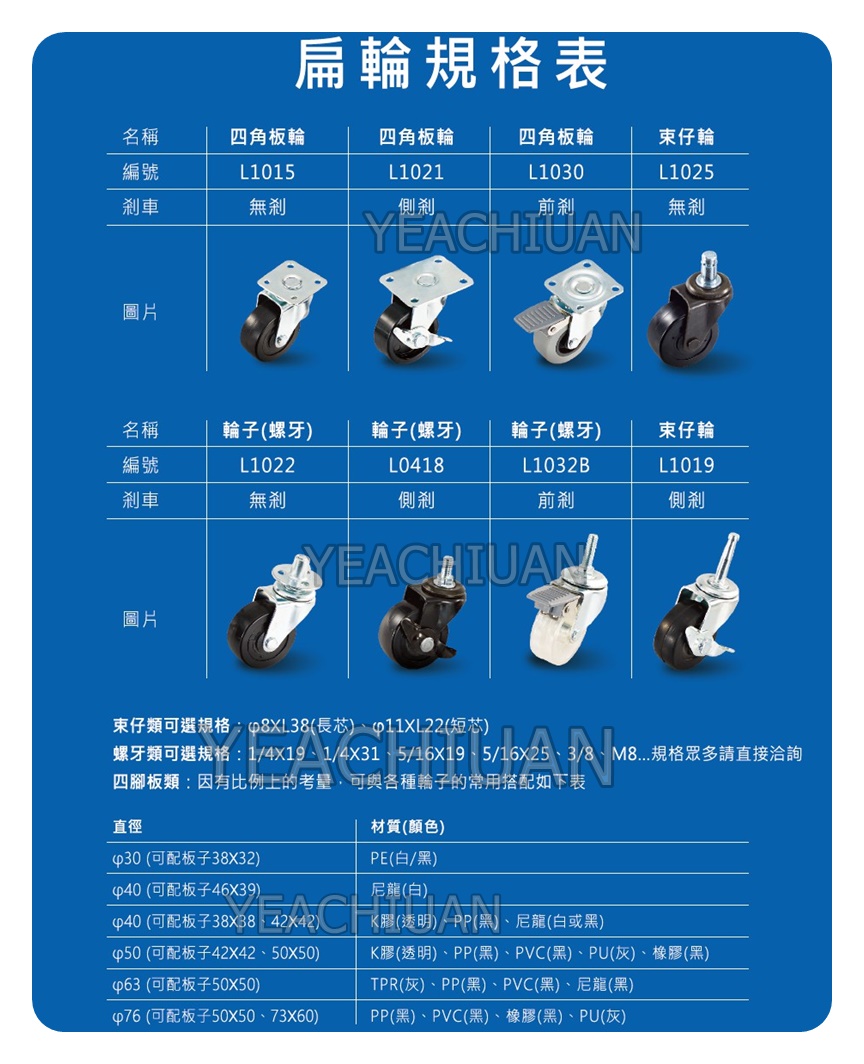

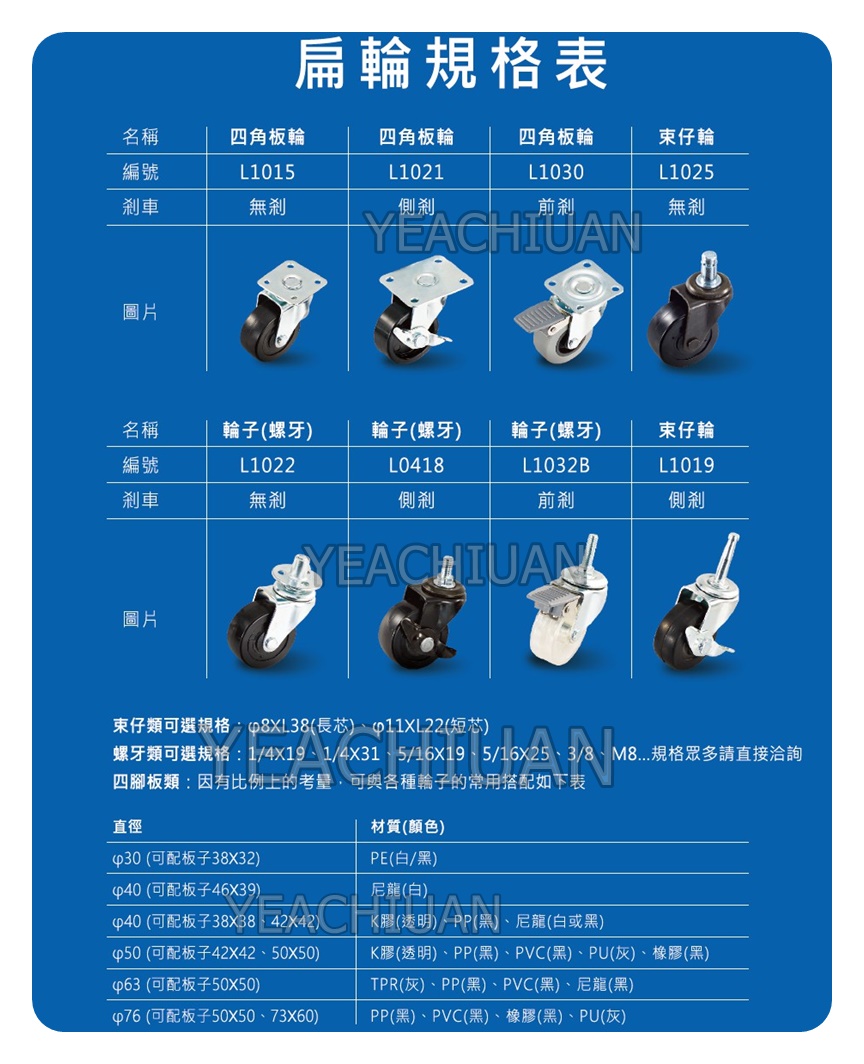

L1015 Series|Quick Guide

| Variant | Mount / Brake | Specs |

|---|---|---|

| Non-brake | Plate-mounted (square plate) | Wheel Ø30–Ø76; plates 38×32 / 38×38 / 42×42 / 50×50 / 73×60 |

| With brake | Plate + side brake | Wheel Ø30–Ø76; same plates |

| Thick plate option | 1.8 mm plate (on request) | Often with 42×42 / 50×50 |

L1015 Series|Quick Guide

| Variant | Mount / Brake | Specs |

|---|---|---|

| Non-brake | Plate-mounted (square top plate) | Wheel Ø30–Ø76; common plates 38×32 / 38×38 / 42×42 / 50×50 / 73×60 |

| With brake | Plate + side brake | Wheel Ø30–Ø76; same plate sizes |

| Thickened plate (option) | Plate thickness 1.8 mm (on request) | Often paired with 42×42 / 50×50 |

Material Overview

| Material | Construction | Key Traits | Recommended Use |

|---|---|---|---|

| K-rubber | Elastic tread | Quiet, shock-absorbing, strong grip; floor-friendly | Indoor floors, displays, household carts |

| PP / PE | Solid plastic | Lightweight, chemical-resistant, cost-effective; higher roll noise | General environments; cost-driven applications |

| Nylon | Engineering plastic (hollow/solid) | Hard, wear-resistant, low rolling resistance | Hard floors, heavy use, workbenches |

| PU | Polyurethane (coated or full PU) | Quiet, durable, higher load; protects floors | Commercial spaces, long-distance pushing |

| TPR | Thermoplastic rubber (full or semi-cover) | Very quiet, shock-absorbing, non-marking | Home/office, delicate floors |

| PVC | PVC coating | Flexible, quiet, grippy; pre-test on dark floors | Grip-focused, moderate loads |

Selection Guide

| Use Case | Recommended Materials | Notes |

|---|---|---|

| Low noise / Floor protection | TPR, PU, K-rubber | Quiet and cushioned; ideal for indoor & commercial floors |

| Cost-driven / General environment | PP, PE | Lightweight, chemical-resistant, budget-friendly |

| Hard floors / Low rolling resistance | Nylon, PU | Nylon for wear & easy rolling; PU balances quietness and wear |

| Traction / Anti-slip | K-rubber, PVC | Great grip; good for slopes or slippery surfaces |

| Chemical / Damp areas | PP, PE, Nylon | Stable against common chemicals; test for actual concentration |

SKU Overview

(A) Frequently Shipped Examples (for reference)

| Item | Wheel Ø | Plate | Plate Thick. | Brake | Tread | Finish / Color | Notes |

|---|---|---|---|---|---|---|---|

| L1015-#8-B05 | Ø40 | 42×42 | 1.8 mm | N | K-rubber | Blue zinc + clear | Lead test 1% passed; salt-spray 48h |

| L1015-#8-C02 | Ø50 | 42×42 | 1.8 mm | N | K-rubber | Zinc + clear | — |

| L1015-#8-C04 | Ø50 | 42×42 | — | N | Solid PP | Zinc + black | — |

| L1015-#8-C04B | Ø50 | 42×42 | — | Y | Solid PP | Zinc + black | — |

| L1015-#8-C07 | Ø50 | 50×50 | 1.8 mm | N | K-rubber | Blue zinc + clear | Lead test 1% passed; salt-spray 48h |

(B) Reference List (Original 01–19)

| No. | Code | Wheel Ø | Plate (mm) | Brake | Tread | Notes |

|---|---|---|---|---|---|---|

| 01 | L1015-#7 | Ø40 | 38×38 | N | Nylon (hollow) | — |

| 02 | L1015-#8 | Ø100 | 73×60 | N | Rubber | — |

| 03 | L1015-#8 | Ø25 | 38×32 | N | PP | Overall height 37 mm |

| 04 | L1015-#8 | Ø30 | 33×44 | N | PP | Overall height 39 mm |

| 05 | L1015-#8 | Ø30 | 38×32 | N | PE | — |

| 06 | L1015-#8 | Ø30 | 38×32 | Y | PE | — |

| 07 | L1015-#8 | Ø40 | 38×38 | N | Nylon (hollow) | — |

| 08 | L1015-#8 | Ø40 | 42×42 | Y | K-rubber | — |

| 09 | L1015-#8 | Ø40 | 42×42 | N | K-rubber | Lead test 1% passed; anti-salt 24h |

| 10 | L1015-#8 | Ø50 | 38×38 | N | Solid PP | — |

| 11 | L1015-#8 | Ø50 | 42×42 | N | K-rubber | — |

| 12 | L1015-#8 | Ø50 | 42×42 | Y | K-rubber | — |

| 13 | L1015-#8 | Ø50 | 50×50 | N | K-rubber | Lead test 1% passed; anti-salt 24h |

| 14 | L1015-#8 | Ø50 | 50×50 | N | K-rubber | — |

| 15 | L1015-#8 | Ø50 | 50×50 | Y | K-rubber | — |

| 16 | L1015-#8 | Ø63 | 50×50 | N | — | |

| 17 | L1015-#8 | Ø63 | 50×50 | Y | — | |

| 18 | L1015-#8 | Ø76 | 50×50 | N | PVC | — |

| 19 | L1015-#8 | Ø76 | 50×50 | Y | PVC | — |