| Item | Description |

|---|---|

| Model | L1046 Ball Transfer Unit (Saucer Type) |

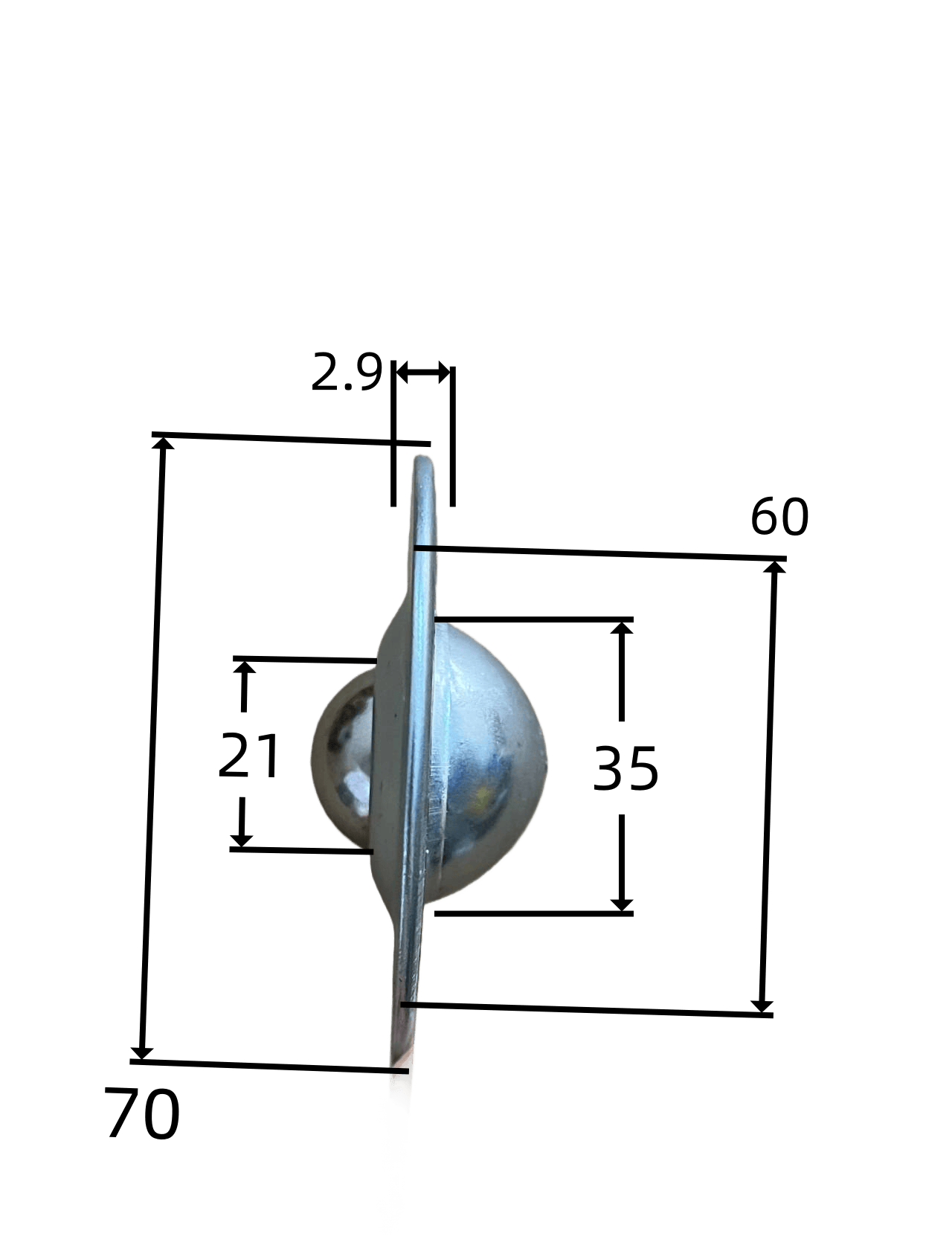

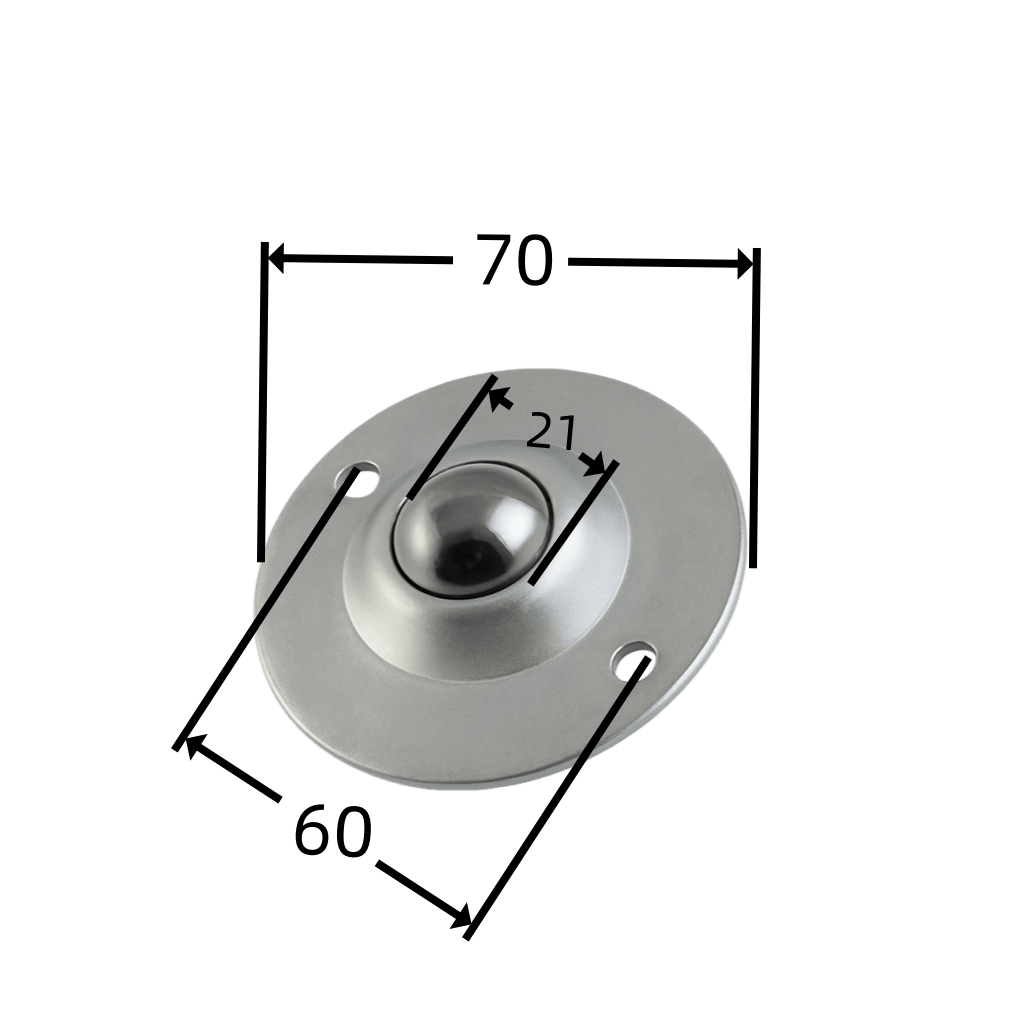

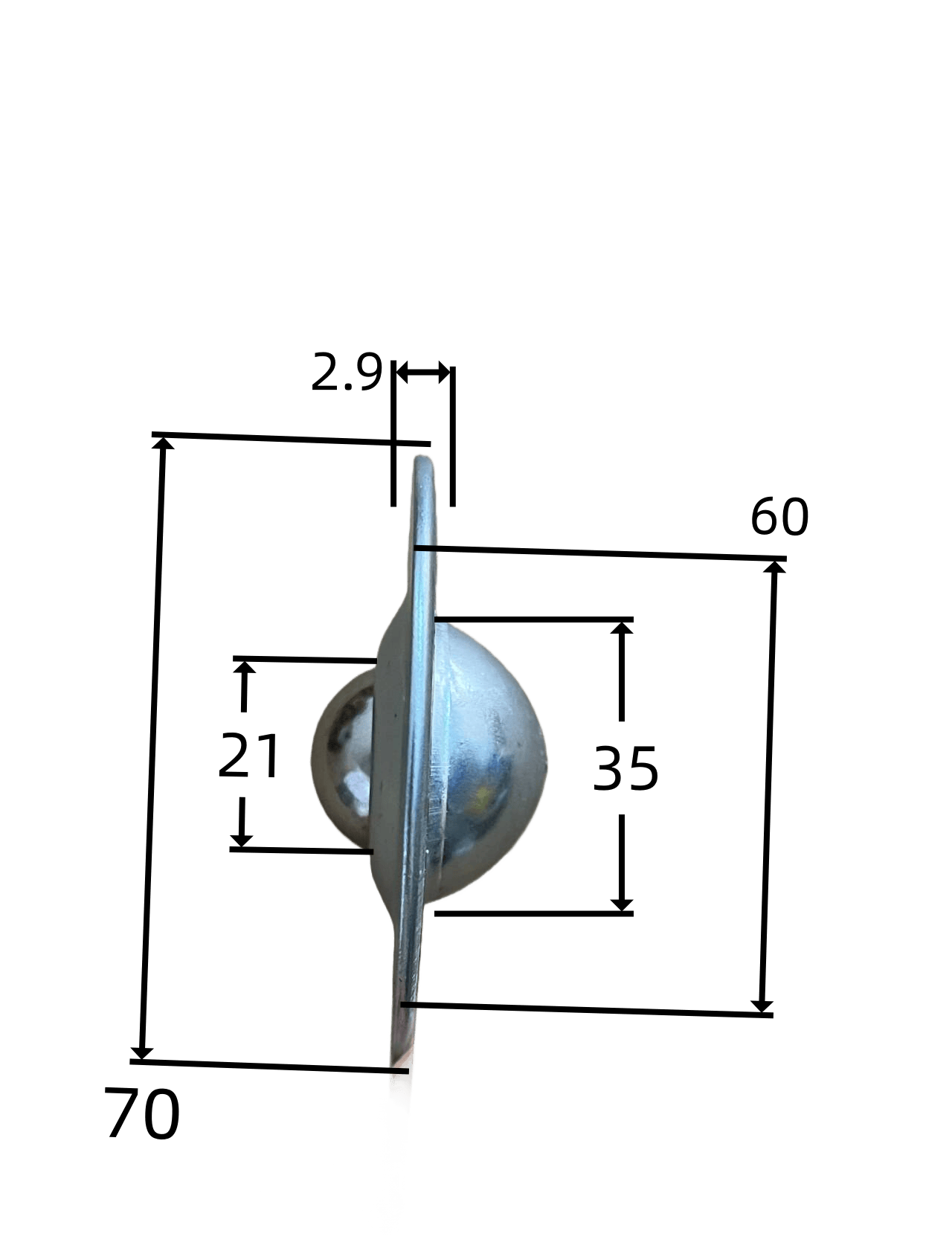

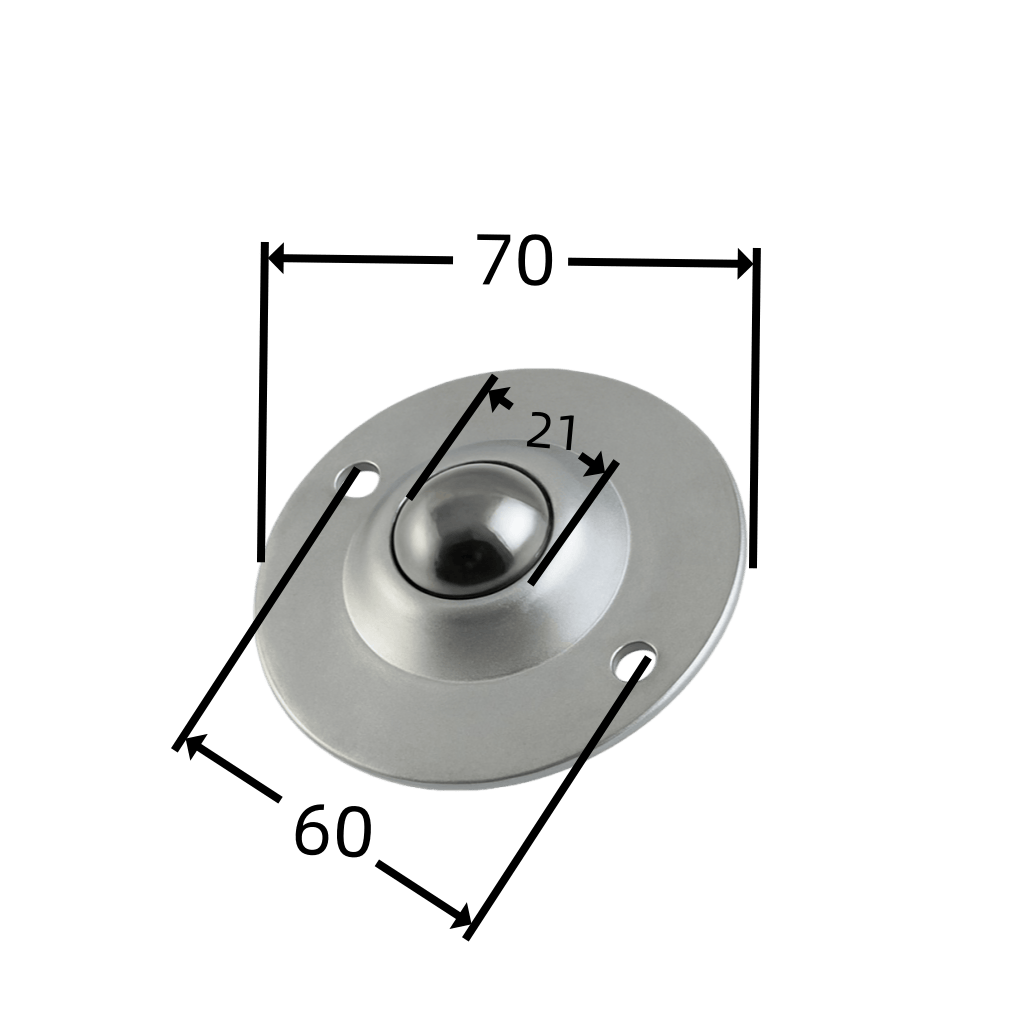

| Flange Diameter | approx. Ø70 mm |

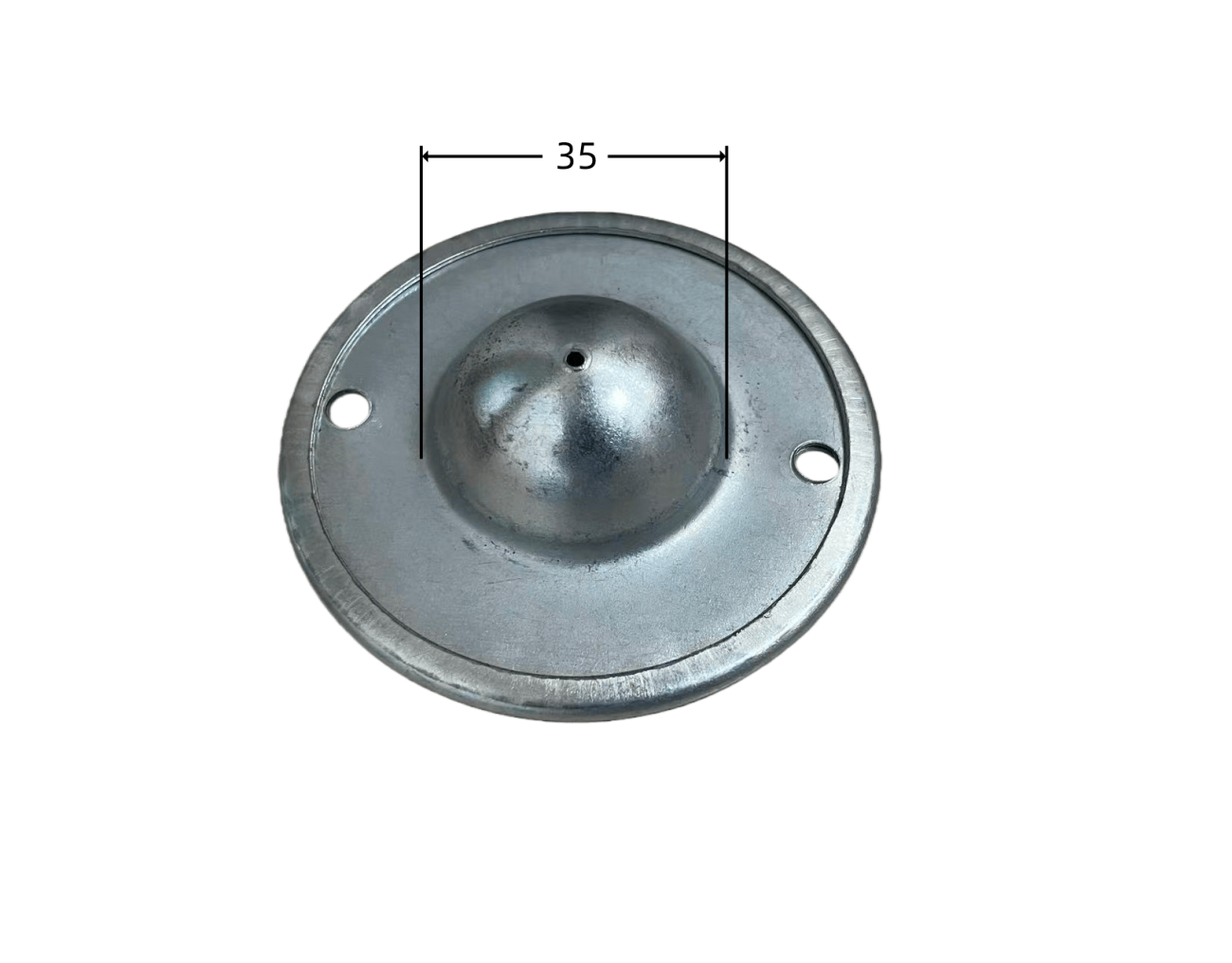

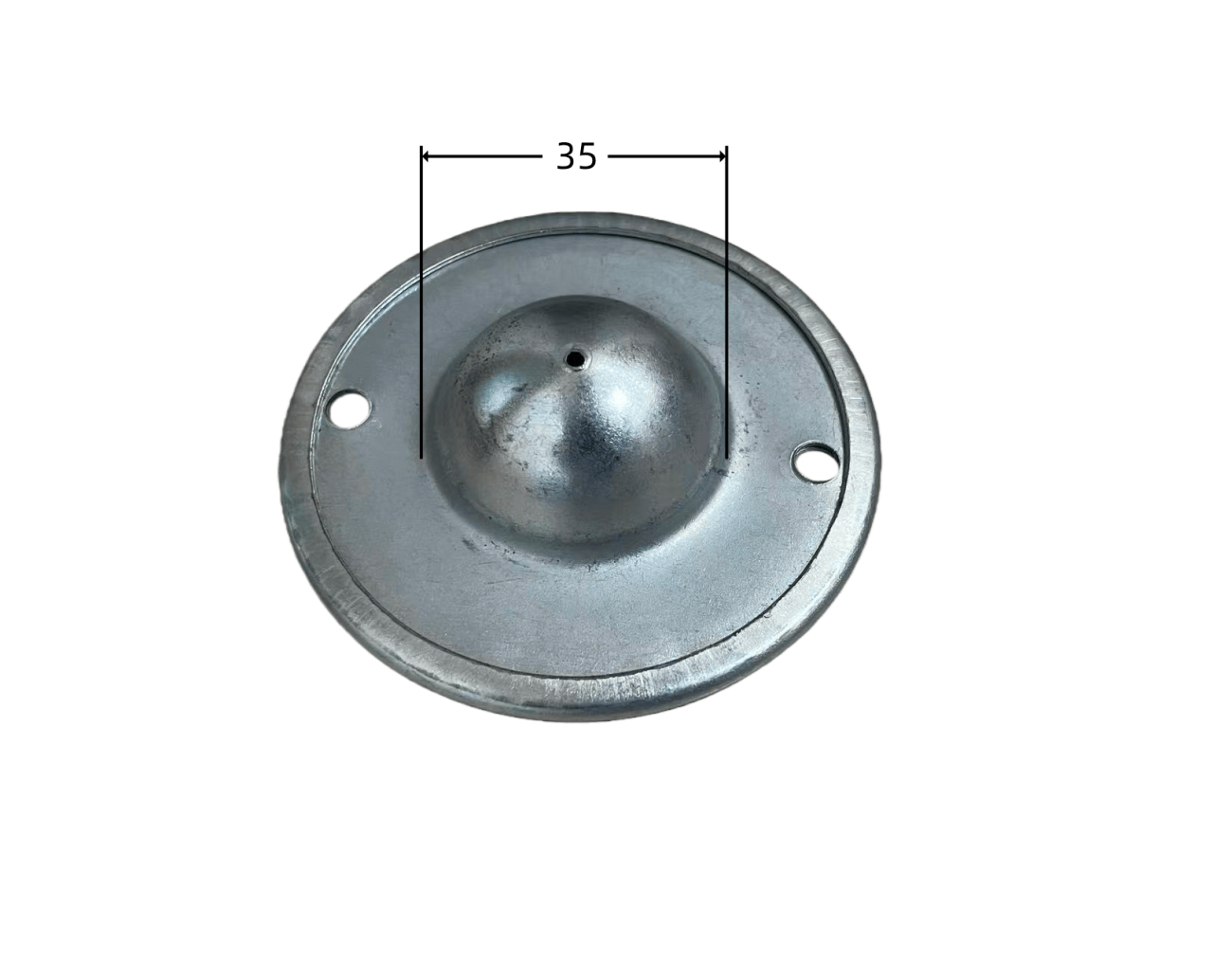

| Main Ball Diameter | approx. Ø35 mm (multi-direction transfer ball) |

| Load Level | 25 kg/PCS (static, single unit, typical indoor workstation condition) |

| Mounting Style | Two-hole surface mounting for easy service and replacement |

| Construction | Steel housing with steel transfer ball |

| Surface Finish | Anti-corrosion coating for standard dry indoor use |

| Core Function | 360° multi-direction sliding and guidance with low starting resistance |

| Typical Use | Sorting tables, loading/unloading stands, infeed angle correction and manual positioning zones |

| Item | Description |

|---|---|

| Model | L1046 Ball Transfer Unit (Saucer Type) |

| Flange Diameter | approx. Ø70 mm |

| Main Ball Diameter | approx. Ø35 mm (multi-direction transfer ball) |

| Load Level | 25 kg/PCS (static, single unit, typical indoor workstation condition) |

| Mounting Style | Two-hole surface mounting for easy service and replacement |

| Construction | Steel housing with steel transfer ball |

| Surface Finish | Anti-corrosion coating for standard dry indoor use |

| Core Function | 360° multi-direction sliding and guidance with low starting resistance |

| Typical Use | Sorting tables, loading/unloading stands, infeed angle correction and manual positioning zones |

| Topic | Details |

|---|---|

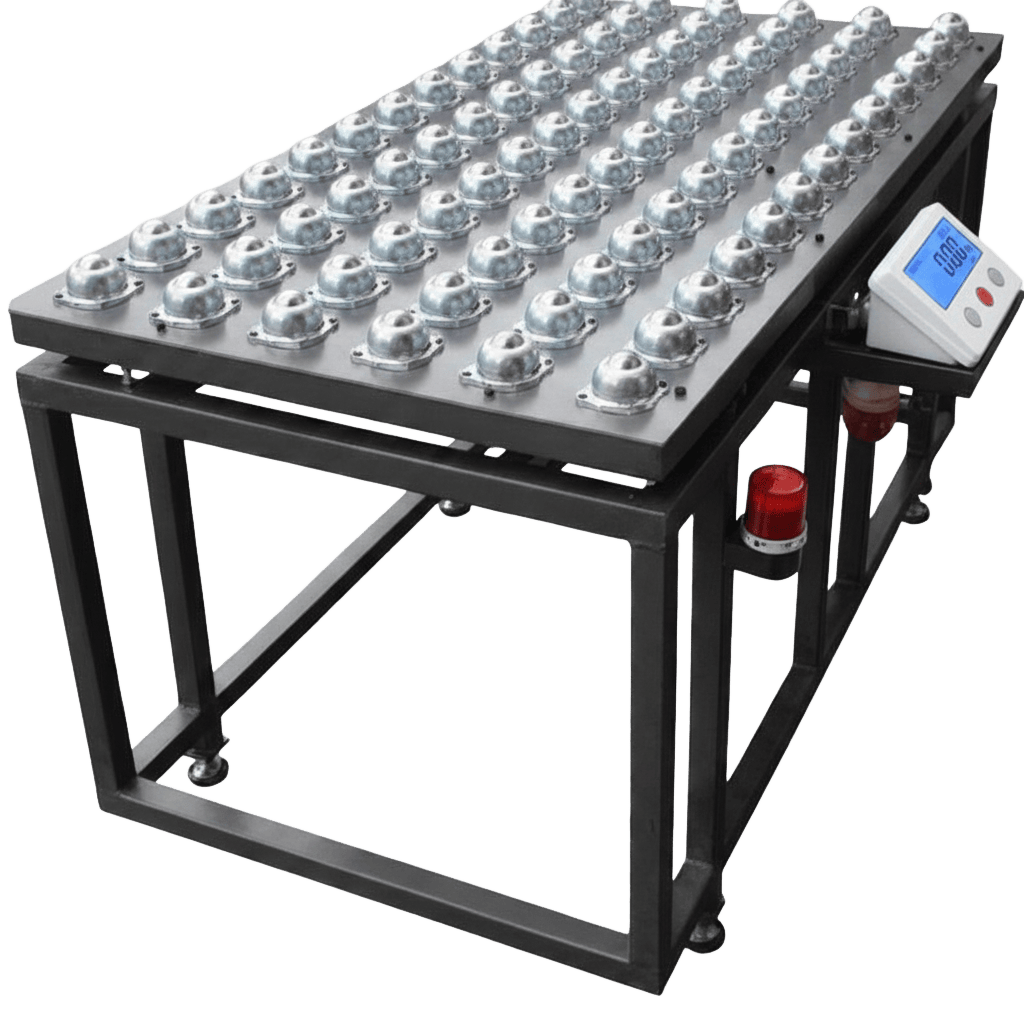

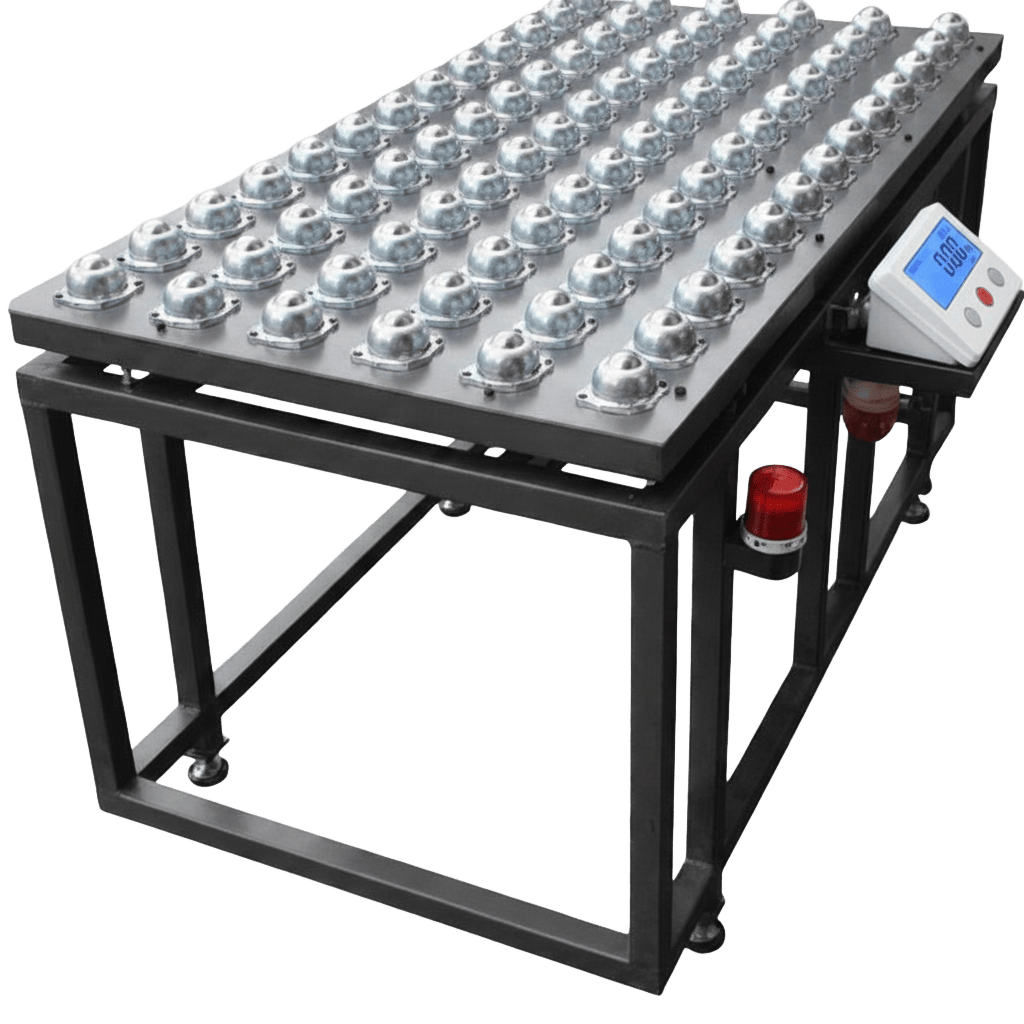

| Operating Principle | The L0416 is a surface-mounted ball transfer unit. The top steel ball supports the workpiece so that the item can move freely in any horizontal direction (360°) with minimal lifting effort. The operator can slide, rotate, align, and feed the part without having to flip or re-grip the entire load. |

| Productivity Impact | Reduces repeated manual lifting and wrist strain. Enables fast turning, orientation correction, and manual infeed control before the next station. Especially effective on high-frequency loading/unloading, pre-check positioning, and carton / panel redirection. |

| Array Layout Guidance | Units are typically arranged in a grid. Spacing should reflect the workpiece weight, footprint, and center of gravity. High-stress or imbalance zones should receive denser placement to avoid overloading a single unit. The mounting surface must be rigid and flat so that multiple units share the load. |

| Usage Conditions & Maintenance | Intended for clean, dry work tables or sorting stands. In dusty, oily, wet, metallic chip or high-humidity environments, inspection and cleaning frequency must be increased to maintain smooth rolling and service life. |

| Application Scenario | Description / Configuration Notes |

|---|---|

| Sorting / Manual Work Table | Cartons, panels and bins can be rotated, pushed sideways or reversed on the table surface. Ideal for manual sorting, inspection staging or temporary orientation changes. Recommended to install multiple units in a matrix so the bottom surface of the item is supported at several points simultaneously. |

| Infeed / Angle Correction | Placed before a conveyor, machine inlet or test station to straighten and align the load before transfer. This reduces jamming, edge impact and misaligned engagement with downstream equipment. |

| Loading / Unloading Assist & Weighing Stand | Helps operators slide medium-weight workpieces on and off a weighing station or inspection bench instead of lifting at awkward angles. High load areas (near the item’s center of gravity) should use denser unit placement to avoid putting all stress on a single unit. |

| Panel / Sheet Handling Platform | Suitable for short-distance manual positioning of flat-bottom boards, metal sheets, etc. The contact surface of the workpiece should be relatively flat. Long-term point loading on sharp edges or corners is not recommended, to avoid local overload or surface denting. |

Disclaimer & Usage Notice:

1. Dimensions / Appearance

- All published figures (including flange approx. Ø70 mm, main ball approx. Ø35 mm, and 25 kg/PCS load level) are based on manual measurement and standard dry indoor reference conditions.

- Actual delivered parts may vary within normal manufacturing tolerances due to measurement method, tooling, production batch, coating thickness, and surface finishing. Minor variation in size, color tone, or surface texture is normal and is not considered a defect.

2. Load Capacity

- The stated 25 kg/PCS is a reference load level for a single unit under static, evenly distributed loading in a typical workstation scenario.

- Real-world capacity depends on the contact area, flatness of the workpiece bottom, center-of-gravity offset, shock / impact, push speed, number of units sharing the load, mounting rigidity and grid spacing. Actual allowable load may be higher or lower.

- The end user must set an appropriate safety factor and perform validation tests before putting the unit into service.

3. Environment & Maintenance

- Dust, metal chips, oil, water, humidity and corrosive atmospheres can affect rolling smoothness, surface finish and service life.

- In such environments, users must increase cleaning frequency and routinely check for binding, rough rolling, corrosion or coating wear, to maintain safe operation.

4. Installation & Operational Safety

- The mounting surface must be sufficiently rigid and flat, and each unit must be fastened securely to avoid loosening, tilting or point overload.

- If the mounting plane deforms, is not fixed properly, or if too few units are used to support the load, a single unit may become over-stressed. This can lead to uncontrolled sliding, drop hazards, personal injury or equipment damage.

- The user is responsible for ensuring that overall table design, load distribution, safety factor, and guarding comply with applicable safety regulations.

5. Responsibility

- Any loss, downtime, property damage or personal injury resulting from improper installation, inadequate load planning, missing safety factors, lack of inspection or use outside the recommended conditions is the responsibility of the end user.

- This product is an industrial assist component. The end user is solely responsible for final compliance, safe installation, load distribution, and appropriate protective measures at the point of use.

6. Specification Changes

- We reserve the right to adjust product appearance, materials, processes, surface treatment and reference data without prior notice.

- Final acceptance criteria are based on the actual delivered batch, inspection reports and mutually confirmed written specifications.