| Item | Description |

|---|---|

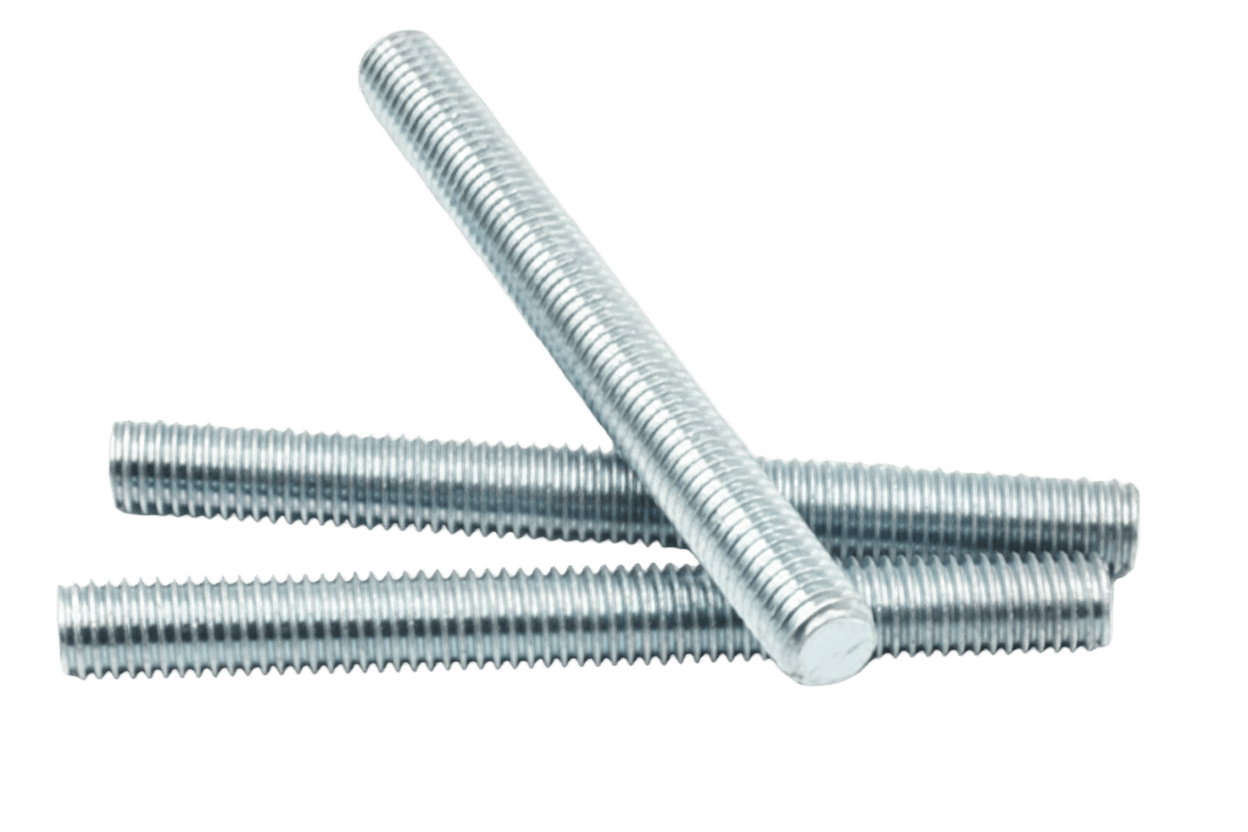

| Product Name | Full Thread Steel Screws / A1017 Imperial Full Thread Series |

| Material | Steel (low carbon). Intended for general fastening, assembly, and maintenance tasks. |

| Surface Finish | Zinc Plated / Color Finish (yellow / rainbow tone). These are general-purpose protective finishes. Minor color variation between batches is normal. |

| Metric Range (mm) | M3–M8. Full-thread lengths available up to 100 mm depending on series. |

| Imperial Range (inch / mm) | 5/16 series (1-3/4" up to 4"), 5/32×3/4, 3/8, and M8×3". |

| Primary Use | Furniture assembly, cabinet / panel mounting, general hardware fastening, in-house maintenance and light-duty structural support. Not an engineered high-load structural bolt. |

| Imperial ↔ Metric Reference | For inch-to-mm conversion, please refer to our imperial / metric reference guide: Chinese: 公制 / 英制換算參考 (中文) English: Imperial / Metric Conversion Guide (English) |

| Series | Available Full-Thread Lengths | Notes |

|---|---|---|

| M3 | M3×10 / ×16 / ×20 / ×25 / ×30 / ×35 / ×40 / ×45 / ×50 | — |

| M4 | M4×12 / ×14 / ×16 / ×18 / ×20 / ×25 / ×30 / ×35 / ×40 / ×45 / ×50 / ×55 | — |

| M5 | M5×16 / ×20 / ×25 / ×30 / ×35 / ×40 / ×50 / ×55 | — |

| M6 | M6×16 / ×18 / ×20 / ×25 / ×30 / ×35 / ×40 / ×45 / ×50 / ×55 | Includes M6×75. |

| M8 | M8×16 / ×20 / ×25 / ×30 / ×35 / ×40 / ×45 / ×50 / ×55 / | — |

| 5/16″ Series (A1017) | 5/16×1-3/4″ / ×3″ / ×3-1/2″ / ×4″ | Imperial lengths. Kept as a dedicated 5/16″ series. |

| 5/16″ (metric length notation) | 5/16×60 mm | Length shown in mm on label. Conversion guide: 中文 / EN |

| 5/32″ Series | 5/32×3/4″ | Imperial length. Conversion guide: 中文 / EN |

| 3/8″ Series | 3/8 | Length shown in mm on label (≈3.94″). Conversion guide: 中文 / EN |

| Special listing | M8×3″ | 8 mm diameter with 3″ length (imperial length notation). See conversion: 中文 / EN |

| Topic | Guidance / Typical Scenario |

|---|---|

| Recommended Use | ・Furniture and cabinet assembly, shelving and display rack mounting ・Indoor fit-out / panel / bracket installation for light structures ・General hardware fastening, repair / replacement work, and standard assembly line fastening ・Office fixtures, warehouse fixtures, light mechanical housings, and maintenance tasks |

| Environment | ・Typical indoor / sheltered conditions: use zinc plated or color finish for basic corrosion protection ・Semi-damp or loading-bay type areas: visually inspect for oxidation over time ・Continuous exposure to high humidity, salt spray, aggressive chemicals, or sustained high temperature is not recommended without engineering approval |

| Not Recommended For | ・Primary load-bearing frames or lifting / suspension points ・Fall-arrest / safety-critical anchors ・High-vibration, high-impact joints in vehicles or heavy machinery ・Locations governed by strict regulatory fastener grades or mandatory certifications |

| Installer Responsibility | ・Final torque setting, embed depth, choice of washers / lock nuts / threadlocker are determined by the installer or engineering team ・If used in high-risk, load-critical, or compliance-regulated areas, higher grade certified fasteners must be selected and approved before use |

| Clause | Disclaimer / Limitation of Use |

|---|---|

| 1 | These products are general-grade full-thread steel screws designed for everyday assembly, indoor fixture mounting, furniture / cabinet work, and routine maintenance or part replacement. They are NOT high-strength structural bolts. |

| 2 | Using these screws as primary load-bearing frame elements, lifting / suspension points, fall-arrest / safety anchors, or in long-term high-vibration / high-temperature / chemically aggressive environments is outside the intended scope and is solely at the user's risk. |

| 3 | Actual performance (tensile, shear, fatigue resistance, loosening behavior) depends on installation torque, thread engagement depth, use of washers / lock nuts / threadlocker, base material (wood, sheet metal, aluminum profile, etc.), humidity, chemical exposure, and ongoing maintenance. The installer is responsible for verifying suitability. |

| 4 | Zinc plated and color finish coatings are general-purpose appearance and corrosion-resistance treatments. Minor shade differences, brightness differences, or local banding between batches are normal industrial tolerances and are not considered defects. |

| 5 | Stated diameters and lengths are reference values for purchasing and assembly communication. Normal dimensional tolerances apply. They are not guaranteed to match any specific engineering drawing tolerance or certified regulatory spec unless explicitly agreed in writing before purchase. |

| 6 | Different regions (building code, fire safety, transportation equipment, public safety, etc.) may legally require specific fastener grades or certifications. The purchaser / installer is responsible for confirming compliance before use in any regulated or safety-critical application. |

| 7 | Final torque control, installation depth, anti-loosening strategy, and periodic inspection / maintenance remain the responsibility of the user or installer. Any damage, loosening, incident, or indirect loss caused by use outside the recommended scope is not covered. |

| Size / Thread Dia. |

10 | 12 | 14 | 16 | 18 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | ||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M3 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||||||||||||||||

| M4 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||||||||||||||||

| M5 | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||||||||||||||||||||

| M6 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||||||||||||||||||

| M8 | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Size / Thread Dia. |

1/2" | 5/8" | 3/4" | 7/8" | 1" | 1-1/8" | 1-1/4" | 1-1/2" | 1-3/4" | 2" | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5/16" | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 3/8" | ● | ● | ● | ● | ● | ● | ● |