Ball-Bearing Slides Guide|2-Section / 3-Section × Feels

Ball-Bearing Slides Guide|2-Section / 3-Section × Feels × Applications (B2B)

For furniture factories, system cabinets and engineering procurement. This page provides a quick selector, length reference, and a model cheat sheet. Focus: side-mount ball-bearing slides. Project & bulk supply only — no single-piece retail.

① Basic: 3-Step Quick Selection

Step 1|Choose Sections

- 2-Section: partial extension, cost-effective, common for general storage.

- 3-Section: full extension; efficient access for tools, files, food service.

Step 2|Choose Feel

- Standard (no soft-close): simple & durable.

- Soft-Close: decelerates at the end; quieter & safer.

- Push-to-Open: handle-less look; reserve push clearance.

Step 3|Match Scenarios

- Storage / tools: 3-Section + Standard or Soft-Close

- Office / files: 3-Section + Soft-Close

- Hospitality / residential: 2- or 3-Section + Soft-Close

- Minimal displays: 2/3-Section + Push-to-Open

①-2: Standard Lengths (8–24", even sizes)

Common supply lengths: 8, 10, 12, 14, 16, 18, 20, 22, 24 inches (≈ 203–610 mm).

Rule of thumb: Inner cabinet depth ≥ nominal slide length + 3–5 mm. 3-Section = full extension; 2-Section = partial extension.

Note: millimeters are rounded nominal values. Always follow the mounting drawing for the chosen series.

② Model Reference & Mapping

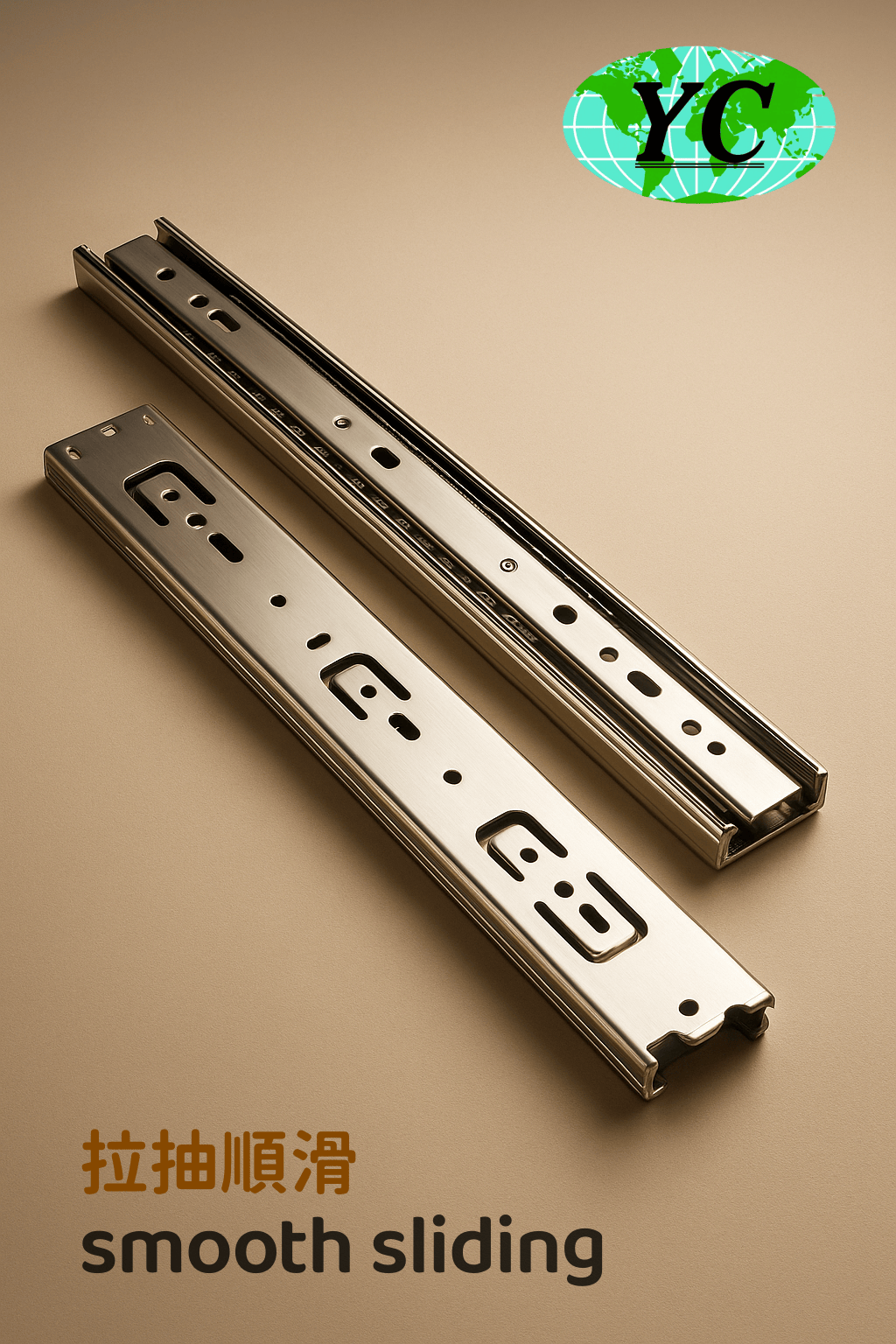

2-Section Slides (Partial Extension)

- G0160: standard 2-section.

- G0160C: 2-section with mounting ears — faster fastening, thin-panel friendly.

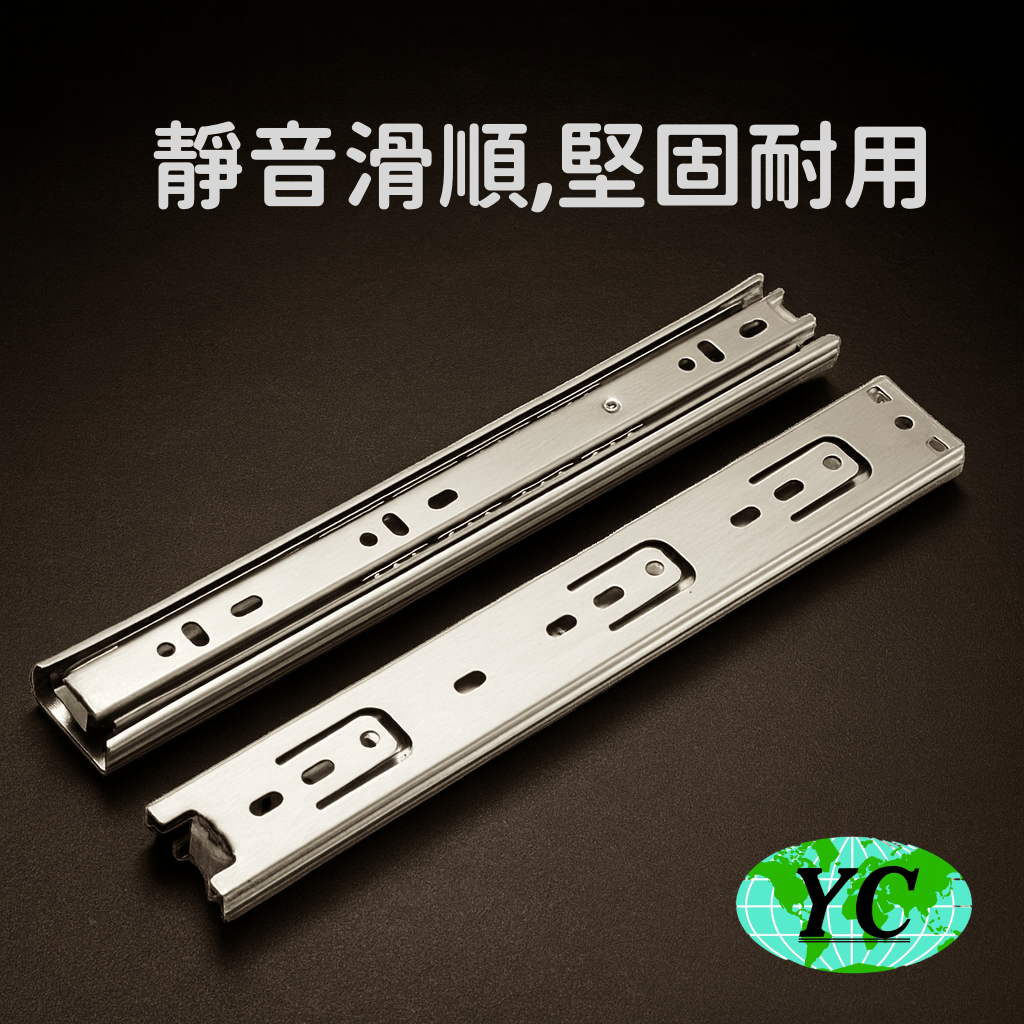

3-Section Slides (Full Extension)

- G0156: general; widths W35 / W37 / W45.

- G0156E: push-to-open; width W45.

- G0156H: soft-close; widths W37 / W45.

- G0156C: with mounting ears — easier alignment & assembly.

- G0159SC: 304 stainless, soft-close.

- G0156*W53: heavy-duty 3-section.

Heavy-Duty 3-Section (G0156*W53)|12–32"

For high loads, large/deep drawers and work carts. Nominal lengths and suggested inner depths:

Note: heavy-duty applications may require derating by posture and cabinet stiffness. Follow sample tests and official drawings.

③ Professional: Engineering & Installation

Geometry & Structure

- Side-mount requires proper side clearance (many series around 0.50" per side ≈ 12.7 mm; follow drawings).

- Large width-to-depth or high load → prefer 3-Section and reinforce cabinet stiffness.

- Adopt standard system hole pitch for faster positioning and maintenance.

Feels & Mechanisms

- Standard: fewer parts, durable, easy maintenance.

- Soft-Close: tune damping to actual load to avoid not-closing / slamming.

- Push-to-Open: sensitive to tolerances; validate rebound travel before MP.

Mounting Posture & Derating

- Default is vertical side-mount. Flat/horizontal or special postures generally require derating and prior sampling.

- Follow drawing for hole usage/spacing to avoid skew, sticking and noise.

Durability & Validation

- Refer to EN / ANSI-BIFMA-type tests, but prioritize sample tests in real scenarios (load × frequency × environment).

- Set a Golden Sample for look & feel as MP acceptance baseline.

④ Advanced: Principles & Risk Control

⑤ FAQ / Contact

How to choose between 2- and 3-Section?

2-Section fits many shallow drawers; for deep or high-frequency drawers, 3-Section is recommended for full extension and efficiency.

Single-piece retail?

This page targets project / bulk inquiries only; single-piece retail is not provided.

Want a faster match? Share drawer dimensions (W × D × H), target load (kg), and whether you need soft-close / full extension / push-to-open. We’ll reply with suggested options and alternatives (final choice subject to samples & tests).

※ Project & bulk supply only.

Disclaimer

1) This page is a general technical/procurement reference. Suitability depends on each project’s dimensions, tolerances, load, duty cycle and environment; final selection must follow sample tests.

2) Inch-to-mm conversions are nominal/rounded. Clearances, hole patterns and derating follow the official drawings/spec for the chosen series.

3) Flat/horizontal or non-standard mounting usually requires derating; specify high-humidity/coastal/chemical exposure to plan materials and maintenance.

4) Soft-close/push-to-open feel & life depend on cabinet stiffness and real load. Establish a Golden Sample and sign off before MP.

5) Scope, lead time and quality liability follow mutually signed contracts/POs. No single-piece retail.