Which Screwdriver Bit Material is Best? S2 vs CR-V vs HSS – Explained Simply

Which Screwdriver Bit Material Is Best? S2, CR-V, HSS—Understand the Key Differences in One Read

Bit material directly dictates torsional strength, cam-out resistance, and service life. This Q&A provides a concise, decision-oriented guide for both DIY and professional use.

Q1: Why does the material matter?

- Torsion & toughness: Too soft bends; too hard chips or fractures.

- Anti-cam-out: Tip integrity and bite reduce stripping.

- Heat-treat quality: Stability and life under continuous powered fastening.

Q2: Common materials & positioning

| Material | Key Characteristics | Recommended Use |

|---|---|---|

| S2 tool steel | High hardness + toughness; excellent torsion; black phosphate improves bite/corrosion | Professional service, assembly lines, heavy powered fastening |

| SVCM+ modified Cr-V | Tougher and more durable than CR-V; strong value when heat-treated well | Mid-to-high frequency maintenance, field work |

| CR-V chrome-vanadium steel | Economical, moderate hardness; wears and strips sooner under high torque | Home DIY, occasional fastening |

| HSS high-speed steel | Great hot-hardness but brittle; designed for cutting/drilling, not torque | Not recommended for bits |

| Carbide (cemented) | Ultra-hard yet fragile; chips under impact; high cost | Precision cutting/forming only, not fastening |

Q3: 5-Star ratings (for fastening use)

| Material | Overall | Torsion | Anti-cam-out | Wear life | Cost efficiency |

|---|---|---|---|---|---|

| S2 | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★☆ | ★★★★☆ |

| SVCM+ | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★★★ |

| CR-V | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | ★★★★★ (entry level) |

| HSS | ★☆☆☆☆ (not for fastening) | ★★☆☆☆ (brittle) | ★☆☆☆☆ | ★★★☆☆ (cutting heat trait) | ★☆☆☆☆ (misapplied) |

| Carbide | ★☆☆☆☆ (not for fastening) | ★☆☆☆☆ (chips under shock) | ★☆☆☆☆ | ★★☆☆☆ (niche value) | ★☆☆☆☆ (costly & misapplied) |

Q4: Quick identification

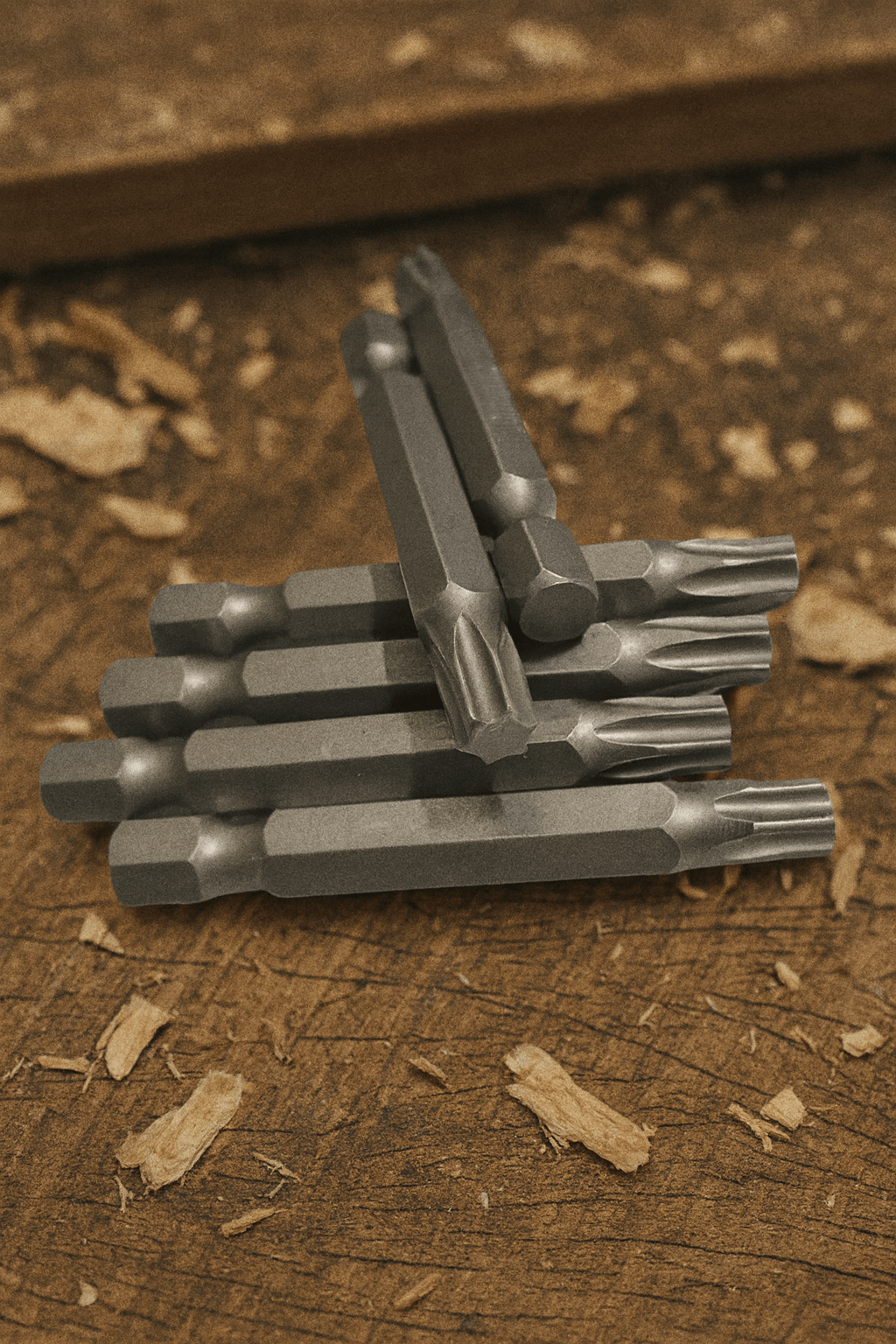

- Color cues: S2 dark gray/black; CR-V light gray; HSS bright silver.

- Labeling: Look for “S2”, “CR-V”, “HSS” on the pack.

- Price trend (same brand): S2 > SVCM+ > CR-V.

Q5: Use-case × material matrix

| Scenario | S2 | SVCM+ | CR-V | HSS | Carbide |

|---|---|---|---|---|---|

| High-torque / long continuous powered fastening | Recommended | Usable | Not recommended | Not applicable | Not applicable |

| Mid-frequency maintenance / site work | Recommended | Recommended | Usable | Not applicable | Not applicable |

| Home DIY / low torque | Usable | Recommended | Recommended | Not applicable | Not applicable |

Q6: Surface & heat treatment essentials

- Surface: Black phosphate improves friction and corrosion resistance; nitriding/carbonitriding increases case hardness and wear resistance.

- Heat treatment & hardness: Typical effective hardness targets around HRC 58–62 (brand-specific). Uniformity matters more than the printed grade alone.

Q7: Use & maintenance tips

- Match drive type/size (PH/PZ/T/Hex) and avoid angled loading.

- Use staged tightening; avoid prolonged high-speed fastening that overheats bits.

- Reduce torque with long bits; replace worn tips promptly to prevent recurring strip-outs.

Procurement spec template (B2B)

- Material grade: S2 / SVCM+ / CR-V

- Surface treatment: black phosphate / nitrided (or none)

- Tip type & size: PH2 / PZ2 / T20 / H4, etc.

- Hardness & QC: target HRC xx–xx; sampling ratio (%)

- Packing: unit per bag, barcode, master carton N.W./G.W. & dimensions

- Use notes: suggested torque range & compatible tool class (per OEM data)

Conclusion

S2 offers the best overall balance; SVCM+ blends durability and value; CR-V suits entry-level or low-frequency tasks. HSS and carbide are designed for cutting, not torque-driven fastening.

Disclaimer (Enhanced)

1) Informational only: This article provides general materials and process knowledge. It is not engineering design, professional advice, or a warranty. Suitability, performance, life, and safety depend on brand processes, batch variation, heat treatment, surface finish, screw grade, base material, torque/RPM settings, operator angle, environment, and maintenance.

2) Spec & batch variation: Appearance, color tone, hardness, dimensions, weight, surface finish, and packing may vary by process and batch. Dimensional tolerances, color differences, and finish effects are subject to the actual goods. Images are illustrative only.

3) Fit-for-purpose responsibility: Users must verify drive type/size (PH/PZ/T/Hex), screw class, substrate, torque/RPM, angle, and conditions, and conduct trials before mass production or field deployment. Any loss from misuse, overload, prolonged high-speed fastening, wrong tip matching, or non-manual-compliant operation is at the user’s risk.

4) Use limitations: HSS and carbide are cutting materials and are not intended for torque fastening. We assume no liability for uses beyond recommended conditions or for modifications to products not authorized by the OEM.

5) Safety & compliance: Follow OEM manuals and occupational safety rules and wear appropriate PPE (goggles, gloves, etc.). Compliance with regional regulations (safety, chemicals, environmental) is the buyer’s/final user’s responsibility.

6) Third-party rights: Any third-party trademarks or model codes are used solely for identification; rights belong to their respective owners.

7) Limitation of liability (to the maximum extent permitted by law): We are not liable for any direct, indirect, incidental, special, punitive, or consequential damages arising from the use of this article or product selection/operation. If liability is mandatory, total liability is capped at the actual purchase price of the related goods and governed by the executed sales contract and/or written warranty terms.

8) Updates & precedence: Content and specifications may change without prior notice. If this article conflicts with a contract, product manual, or official technical documentation, the latter shall prevail.